In part 3, we will explore the structural differences and rotation principles of brushless motors, comparing them with brushed DC motors and AC motors.

| Brushless Motor Structure and Rotation Principles |

Brushless motors maintain the excellent controllability of DC motors while replacing their brushes and commutator with electronic components. This design eliminates mechanical wear and improves reliability and efficiency.

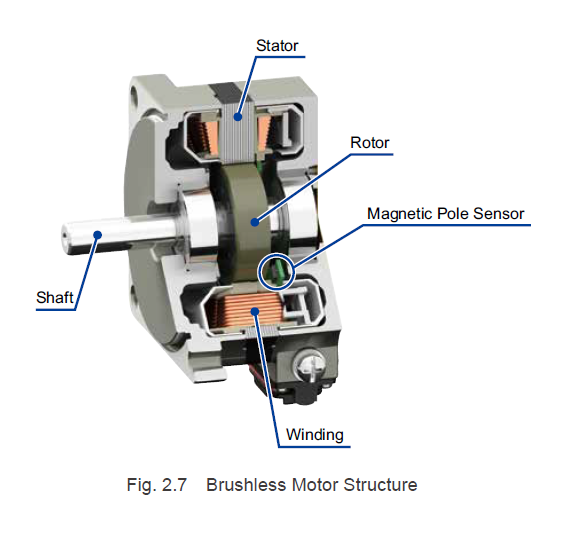

2.2.1 Brushless Motor Structure

The rotor contains permanent magnets, and the stator contains windings, which is the opposite of the structure in a brushed DC motor. In brushed DC motors, the commutator and brushes are used to switch current direction, but in brushless motors, this is done electronically. Instead, magnetic pole sensors (such as Hall elements or Hall effect ICs) detect the position of the rotor's magnets, allowing the drive circuit to control the current flow through the stator windings accordingly.

2.2.2 Brushless Motor Rotation Principles

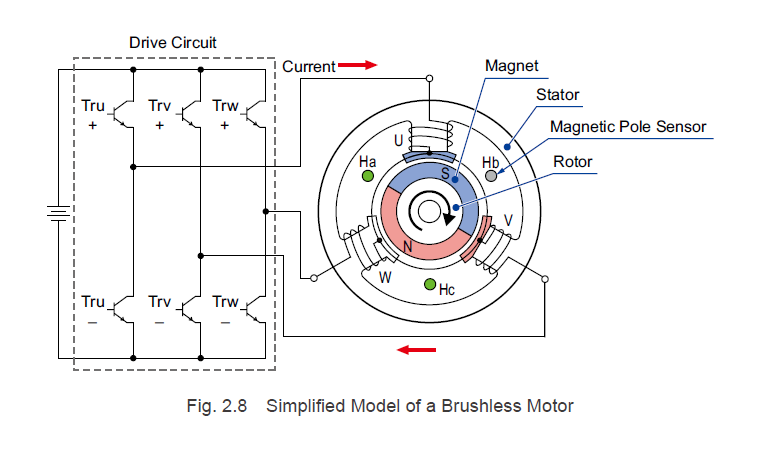

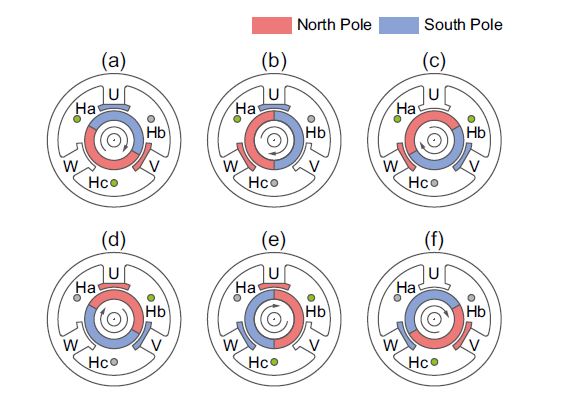

To understand how brushless motors work, we can use a simplified three-phase, two-pole model. The rotor has north and south poles spaced 180° apart, and magnetic pole sensors (Ha, Hb, Hc) are placed 120° apart to detect the rotor’s position. The stator windings (U, V, W) are also spaced 120° apart and offset by 60° from the sensors.

When current flows through the stator windings, it generates a magnetic field that interacts with the rotor’s permanent magnets. By switching the current between different windings based on sensor feedback, the motor rotates. This process repeats, creating a continuous rotating magnetic field that drives the rotor forward.

As the rotor turns, the sensors detect its position, and the drive circuit switches the current through the appropriate windings. This creates a continuous rotational motion. The direction of rotation can be reversed by changing the sequence of current flow through the windings.

In summary, brushless motors operate by directing current through the stator windings based on signals from magnetic pole sensors. A drive circuit controls this process, making it efficient and reliable without the need for physical brushes or commutators.

| TIP: Brushless Motor Currents |

| Direct current is applied to the drive circuits of brushless motors, but an alternating current flows through the motor. For this reason, brushless motors are sometimes called AC synchronous motors. |

2.2.3 Brushless Motor Characteristics

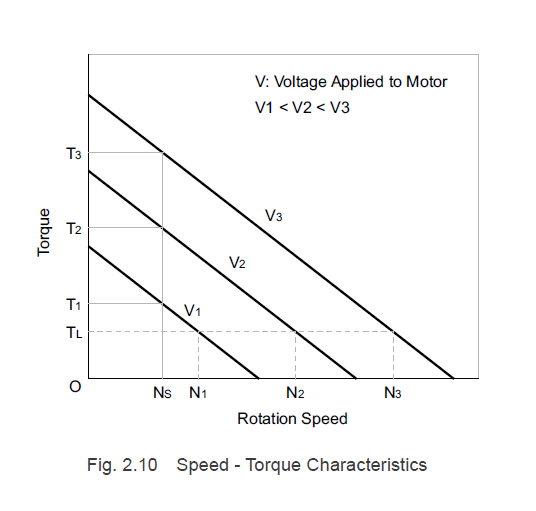

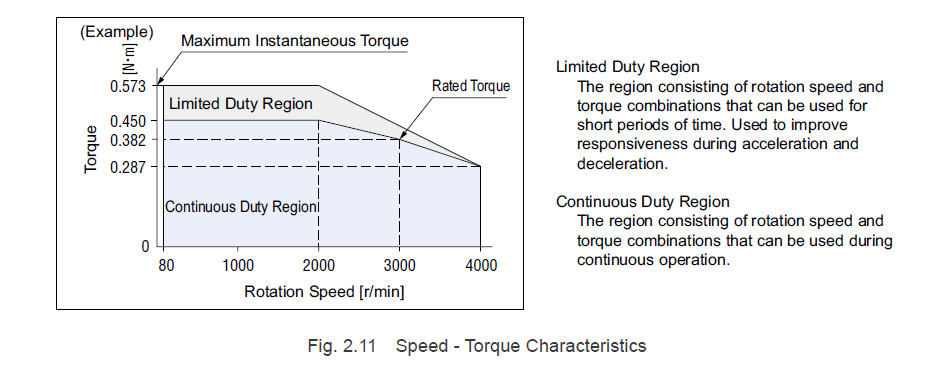

Brushless motors have speed-torque characteristics similar to those of brushed DC motors, with a sloping curve where torque increases as speed decreases. However, due to the lack of brushes, they avoid issues like wear, noise, and maintenance. But at high speeds, torque decreases, which can affect performance and lifespan if not managed properly.

Excessive current can cause demagnetization of the rotor's permanent magnets, leading to reduced performance or failure. Therefore, drive circuits often include current limiting features to protect the motor under heavy loads.

| TIP: Rotor Magnet Demagnetization |

| Permanent magnets are magnetized using strong magnetic fields. However, excessive current can generate a diamagnetic field in the stator, weakening the rotor’s magnetic field. This is known as demagnetization. |

Oriental Motor's systems are designed to prevent demagnetization even under maximum torque conditions.

2.2.4 Brushless Motor Features

Compared to brushed DC motors, brushless motors offer several advantages:

- Excellent controllability and no need for periodic maintenance due to the absence of brushes and commutators.

- Reduced noise and no mechanical wear from brushes.

- Higher speed accuracy due to feedback control via magnetic sensors.

- Ability to detect abnormal behavior during operation.

Compared to inverter-controlled AC motors, brushless motors are more compact, efficient, and suitable for battery-powered applications. They also offer consistent torque across a wide range of speeds, making them ideal for industrial and precision applications.

Due to their reliability, efficiency, and compact size, brushless motors are increasingly preferred over traditional brushed DC motors, especially in environments requiring long life, high accuracy, and low maintenance.

Interested in learning more?

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3d618188-d46e-415b-8663-0510a224fdde', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3d618188-d46e-415b-8663-0510a224fdde', {"useNewLoader":"true","region":"na1"});

Â

|

Previous Post

|

Next Post

|

Learn more about Oriental Motor's  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '0711e763-c067-4db9-8633-e45e46791b16', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '0711e763-c067-4db9-8633-e45e46791b16', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'b434492d-37fd-4145-85d0-d88a2d703111', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'b434492d-37fd-4145-85d0-d88a2d703111', {"useNewLoader":"true","region":"na1"});

Â

Subscribe (top right corner) to receive monthly updates!

Nylon Open-end Zipper Machines

HTD is a professional mechanical manufacturing enterprise with research, development, production, and sales, which specialized in making full line machines, especially in zipper machines. We have experience in zipper making machine manufacturing for more than 14 years.

Our main products can be divided into: Plastic Zipper Machines, Nylon Zipper Machines, Metal Zipper Machines , and Invisible Zipper Machines.

All of our machines will be well tested before shipment. Before shipment, we will send to our customers testing video (no shorter and 120 seconds). Only with confirmation, we will arrange shipment.

We offer professional after-sales service, such as installation instruction, training and machine repairing. To provide customers high-quality products with competitive prices and effective service is always our aim of work.

We always respond to our customers within 24 hours: on-line service 24/7!

Turkey local service are available as well! We will send technician for troubleshooting, repairing, training or other service within 72 hours!

All of our products have passed through ISO9001:2008 and gained CE certifications.

Any of your comments and requests are highly values! Please do not hesitate to contact us for your special offer!

Nylon Zipper Making Machine,Open-End Zipper Machines,Nylon Zipper Machines,Automatic Zipper Cutting Machine

HTD MACHINERY , https://www.jeehtd.com