Hi everyone,

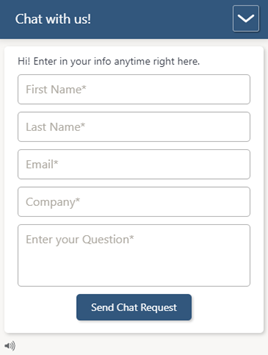

We're excited to announce that we've added a **live chat** feature to the Engineering Notes blog to provide you with faster and more direct support. This new tool allows our technical support engineers in the U.S. to assist you in real time with any questions, troubleshooting, or motor sizing needs.

The live chat is located in the bottom right corner of the screen. Simply click on it to open the window and start chatting with our experts. You can also expand the chat box for a better view.

Our support team is available from **8:30 AM EST to 5:00 PM PST**, Monday through Friday. If you have questions outside of these hours, feel free to email us at [support@orientalmotor.com](mailto:support@orientalmotor.com) or [techsupport@orientalmotor.com](mailto:techsupport@orientalmotor.com). We also encourage you to use our **Motor Sizing Tools**, visit the **Engineering & Design Resources** section for product forums (FAQs), or watch our **application videos** for tutorials and examples.

Additionally, we’ve turned off comments on this blog post to maintain a focused and helpful environment. We appreciate your understanding and look forward to assisting you through the new live chat feature!

Let us know if you need help — we’re here for you!

Heat Surface

Membrane/Water Wall Material and Arrangement:

The

furnace and roof are made up of membrane water wall and hung on the

steel structure by upper hanging suspender of water cooling upper

header. Furnace intersecting surface is 3170×5290mm2 and

the elevation of top furnace is 28877mm. The membrane water wall is

made up of φ60×5 and 6×45 welding steel flat. The combustion chamber is

made of φ60×4 steel tube and welded with pin to fasten refractory

material. The upper part of combustion chamber connects with furnace

membrane water wall. The lower part connects with water cooling wind

chamber and water cooling air distributor. The water cooling wind

chamber is made up of φ60 steel tube and welded with pins to fasten the

refractory material. The water cooling distributor is welded with

φ60 steel tube and 6X45 steel flat. The small holes on the steel flat

connects with the funnel cap.

The

furnace divides left, right, front and back water circulation circuit.

The steam leading tube is made up of φ133×5 and φ108×4.5 steel tube. The

downcomer is made up of φ108×4.5 steel tube. Install the blowdown valve

under the lower header to periodic blow down.

Heat Surface,Scraped Surface,Heat Transfer Surface,Heating Surface For Coal Boilers

Jinan Boiler Group Co., Ltd. , https://www.jinanboiler.com