Explore our comprehensive guide to steel flanges, which will help you gain a deep understanding of what a steel flange is and how to choose the right one for your application needs.

Steel flanges are typically attached to other pipe fittings using welding attachments and are sealed to other flanges with bolts and gaskets. These components play a crucial role in industrial processes, such as in water pipelines, oil filtration machinery, food processing equipment, and pressure vessels, among others.

Over the years, various specifications have been developed for these industrial elements, each serving an important function across multiple industries.

It's essential to ensure that pipes are connected safely to prevent leaks in the piping system. Flanges maintain accurate connections and help the system operate safely for a longer period.

Table of contents

- Steel Flanges Specification

- Different Types of Flanges

- Steel Pipe Flange Material Grades

- Galvanized Pipe Flange Working Pressure

- Steel Flange Dimension Chart

- WNRF Flange Weight Chart

- Steel Flange Face Types

- Reducing Weld Neck Flange Thickness Chart

- Steel Pipe Flange Torque Chart

- Weld Neck Pipe Flange Bolt Chart

Steel Flanges Specification

| Steel Flanges Size |

|

|---|---|

| Flange Face Types |

|

| WNRF Flange Standards |

|

| Steel Pipe Flange Pressure class |

|

| Steel Flanges Types |

|

| Steel Flanges Manufacturer in India, Buy Weld Neck and Galvanized Pipe Flange in Different Sizes at Lowest Price in India | |

Manufacturing standard of pipe flanges is ASME B16.5

This standard covers NPS ½ to NPS 24 metric inches, including pressure-temperature ratings, dimensions, tolerances, materials, sizes, marking, testing, and flange opening methods.

Flange class ratings include 150, 300, 400, 600, 900, 1500, and 2500, available in sizes from NPS ½ to NPS 24 metric inches. Class 2500 flanges are available up to NPS 12 in both metric and U.S. units, with bolt diameters and hole sizes specified in inches.

ASME B16.5 flanges are made from forged or cast materials. Blind flanges and certain reducing flanges can be fabricated from forged, cast, or plate materials. This standard also includes requirements for bolting, gaskets, and flange joints.

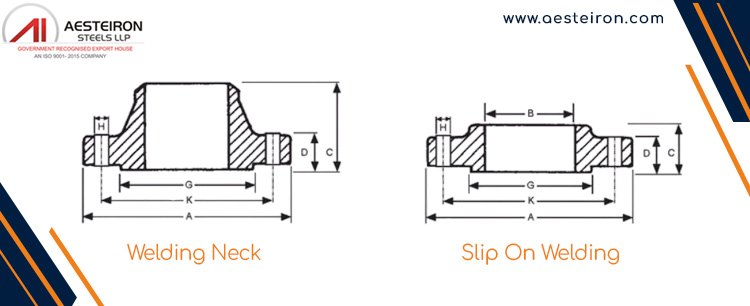

Different Types of Flanges

| Weld Neck Flanges |  |

|

|---|---|---|

| Slip On Flanges |  |

|

| Socket Weld Flanges |  |

|

| Lap Joint Flanges |  |

|

| Threaded Flange |  |

|

| Blind Flange |  |

|

| Orifice Flange |  |

|

| Long Welding Neck Flange |  |

|

| Weldoflange and Nipoflange |  |

|

| Expander and Reducing Flange |  |

|

Steel Pipe Flange Material Grades

| Material | Grades | Features |

|---|---|---|

| Carbon steel |

|

|

| Stainless steel |

|

|

| Alloy steel |

|

|

| Duplex |

|

|

| Super duplex |

|

|

| Nickel Alloys Flanges |

|

|

Reducing weld neck flange have pressure rating of class 150 to class 2500

ASME creates the flange class, considering several pressure and temperature ratings. There are seven classes: 150, 300, 400, 600, 900, 1500, and 2500. Reducing weld neck flanges can operate at these pressure ratings. The pressure rating specifies the maximum allowable pressure at a given temperature. For example, a class 2500 flange can withstand higher pressure and is heavier than a class 1500 flange. A class 2500 flange indicates it is suitable for use at this rated temperature without cracking or damage.

Galvanized Pipe Flange Working Pressure

| Working Pressure Bar [psi] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temp (°C) | (°F) | 29 – 38 | (-20.2 – 100) | 50 | -122 | 100 | -212 | 150 | -302 | 200 | -392 | 250 |

| Class | 150 | 19.6 | -284 | 19.2 | -278 | 17.7 | -257 | 15.8 | -229 | 13.8 | -200 | 12.1 |

| 300 | 51.1 | -741 | 50.1 | -723 | 46.6 | -675 | 45.1 | -654 | 43.8 | -635 | 41.9 | |

| 400 | 68.1 | -987 | 66.8 | -968 | 62.1 | -900 | 60.1 | -871 | 58.4 | -846 | 55.9 | |

| 600 | 102.1 | -1480 | 100.2 | -1452 | 93.2 | -1351 | 90.2 | -1307 | 87.6 | -1270 | 83.9 | |

| 900 | 153.2 | -2220 | 150.4 | -2180 | 139.8 | -2026 | 135.2 | -1959 | 131.4 | -1904 | 125.8 | |

| 1500 | 255.3 | -3700 | 250.6 | -3632 | 233 | -3377 | 225.4 | -3267 | 219 | -3174 | 209.7 | |

| 2500 | 425.5 | -6167 | 417.7 | -6054 | 388.3 | -5628 | 375.6 | -5443 | 365 | -5290 | 349.5 | |

| Temp (°C) | (°F) | -482 | 300 | -572 | 325 | -617 | 350 | -662 | 375 | -707 | 400 | -752 |

| Class | 150 | -175 | 10.2 | -148 | 9.3 | -135 | 8.4 | -122 | 7.4 | -107 | 6.5 | -94.2 |

| 300 | -607 | 39.8 | -577 | 38.7 | -561 | 37.6 | -545 | 36.4 | -528 | 34.7 | -503 | |

| 400 | -810 | 53.1 | -770 | 51.6 | -748 | 50.1 | -726 | 48.5 | -703 | 46.3 | -671 | |

| 600 | -1216 | 79.6 | -1154 | 77.4 | -1122 | 75.1 | -1088 | 72.7 | -1054 | 69.4 | -1006 | |

| 900 | -1823 | 119.5 | -1732 | 116.1 | -1683 | 112.7 | -1633 | 109.1 | -1581 | 104.2 | -1510 | |

| 1500 | -3039 | 199.1 | -2886 | 193.6 | -2806 | 187.8 | -2722 | 181.8 | -2635 | 173.6 | -2516 | |

| 2500 | -5065 | 331.8 | -4809 | 322.6 | -4675 | 313 | -4536 | 303.1 | -4393 | 289.3 | -4193 | |

Standard size range of socket weld and slip on flanges is 1/2″ to 24″

The standard size range for socket weld and slip on flanges is crucial for many industries, as it provides fastening for piping systems. These flanges are usually manufactured in standard sizes from ½†to 24â€.

Understanding the categorization and differences between flanges across countries is important for seamless integration and consistency in global projects.

Flange standardization ensures safety and uniformity across the broad range of global industries, enabling international trade by providing a common base for fabricators, suppliers, and consumers.

Steel Flange Dimension Chart

| NPS | 01/2 | 03/4 | 1 | 1 1/ 2 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|---|---|

| O.D.(Inch) | 3.5 | 3.88 | 4.25 | 5 | 6 | 7.5 | 9 | 10 | 11 |

| SORF Bore Inner Dia (MM) | 9.65 | 11.17 | 34.54 | 49.53 | 61.97 | 90.67 | 116.07 | 143.7 | 170.68 |

| Bolt Holes No | 4 | 4 | 4 | 4 | 4 | 4 | 8 | 8 | 8 |

| Holes Dia (MM) | 15.74 | 15.74 | 15.74 | 15.74 | 19.05 | 19.05 | 19.05 | 22.35 | 22.35 |

| Bolt Circle (Inch) | 2.38 | 2.75 | 3.12 | 3.88 | 4.75 | 6 | 7.5 | 8.5 | 9.5 |

| WNRF Bore Inner Dia (MM) | 22.35 | 27.68 | 26.67 | 40.89 | 52.57 | 77.97 | 102.36 | 128.2 | 154.17 |

| Dia Hub Base (Inch) | 15.74 | 20.82 | 1.94 | 2.56 | 3.06 | 4.25 | 5.31 | 6.44 | 7.56 |

| Min WT (MM) | 1.19 | 1.5 | 12.7 | 15.74 | 17.52 | 22.35 | 22.35 | 22.35 | 23.87 |

| RF Dia(Inch) | 1.38 | 1.69 | 2 | 2.88 | 3.62 | 5 | 6.19 | 7.31 | 8.5 |

| NPS | 8 | 10 | 12 | 16 | 18 | 20 | 22 | 24 | |

| O.D.(Inch) | 13.5 | 16 | 19 | 23.5 | 25 | 27.5 | 29.5 | 32 | |

| SORF Bore Inner Dia (MM) | 221.48 | 276.35 | 327.15 | 410.46 | 461.77 | 513.08 | 564.38 | 615.95 | |

| Bolt Holes No | 8 | 12 | 12 | 16 | 16 | 20 | 20 | 20 | |

| Holes Dia (MM) | 22.35 | 25.4 | 25.4 | 28.44 | 31.75 | 31.75 | 35.05 | 35.05 | |

| Bolt Circle (Inch) | 11.75 | 14.25 | 17 | 21.25 | 22.75 | 25 | 27.25 | 29.5 | |

| WNRF Bore Inner Dia (MM) | 202.69 | 254.5 | 304.8 | 387.35 | 438.15 | 488.95 | 539.75 | 590.55 | |

| Dia Hub Base (Inch) | 9.69 | 12 | 14.38 | 18 | 19.88 | 22 | 24.25 | 26.12 | |

| Min WT (MM) | 26.92 | 28.44 | 30.22 | 35.05 | 38.1 | 41.14 | 44.45 | 45.97 | |

| RF Dia(Inch) | 10.62 | 12.75 | 15 | 18.5 | 21 | 23 | 25.25 | 27.25 |

WNRF Flange Weight Chart

| NPS | 1/2 | 3/4 | 1 | 1¼ | 1½ | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|---|---|---|---|

| WNRF (KG) | 0.9 | 0.9 | 1.4 | 1.4 | 1.8 | 2.7 | 5.2 | 7.4 | 9.5 |

| SORF (LBS) | 1.1 | 1.98 | 1.98 | 3.08 | 3.08 | 5.07 | 9.03 | 13 | 14.99 |

| BRF (LBS) | 1.98 | 1.98 | 1.98 | 3.08 | 3.96 | 5.07 | 9.03 | 16.97 | 19.84 |

| NPT (KG) | 0.5 | 0.9 | 0.9 | 1.4 | 1.4 | 2.3 | 4.1 | 5.9 | 6.8 |

| LJRF (KG) | 0.5 | 0.9 | 0.9 | 1.4 | 1.4 | 2.3 | 4.1 | 5.9 | 6.8 |

| SWRF (LBS) | 1.98 | 1.98 | 1.98 | 3.08 | 3.08 | 5.07 | 9.03 | 13 | 14.99 |

| NPS | 6 | 8 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| WNRF (KG) | 11.7 | 18.9 | 39.6 | 51.3 | 63 | 74.3 | 88.7 | 101.3 | 120.6 |

| SORF (LBS) | 18.95 | 29.76 | 63.49 | 89.28 | 105.16 | 128.97 | 163.8 | 183.64 | 218.25 |

| BRF (LBS) | 26.89 | 46.73 | 122.13 | 138.8 | 178.57 | 218.25 | 282.85 | 352.29 | Aero hand rest Mould,Aero back rest Mould,Aviation instrument panel parts mould,Aviation instrument panel shell mould,Aero backrest injection Mould, Aviation instrument panel parts injection mould Dongguan Hongke Plastic Precision Mould Co.,Limited , https://www.hongkemold.com |