| Process | Lab use, experiment |

| Application | Color masterbatch, filler MB, reinforced material etc. |

| Output | 1-10kg/h, depending on the condition of raw material, formulation and processing, etc. |

| NO. | Name |

| 3 | Main feeder |

| 4 | Twin Screw Extruder |

| 5 | Electric Control System (cabinet) |

| 6 | Strands Pelletizing System |

| Machine Size | Screw Diameter (mm) | L/D | Screw Speed Max. (rpm) | Motor power (Kw) | Torque per shaft (Nm) | Throughput rate (kg/h) |

| TSE-20 | 22 | 36-44 | 500 | 5.5 | 43 | 1-10 |

| TSE-30 | 31 | 36-44 | 600 | 15 | 119 | 5-30 |

| TSE-35 | 35.6 | 36-44 | 600 | 22 | 175 | 30-70 |

Representative Material:

Mixing Nature-Changing: PE, PP, PS+SBS, PA+EPDM, PP+NBR, EVA+Silicon rubber

PE, PA, PC, CPE+ABS, ABS+TPU, PBT+PET, PP+PE

Filling Nature-Changing: PE, PP, EVA, etc. + Calcium carbonate, talcum powder, titanium powder

PP, PA, ABS + ferrous powder, sulfuric powder, ceramic powder

Functional Machine Pellets: PP, PA, ABS, PBT, etc. + anti-burning agent and other auxiliary agents: combustion-supporting machine pellets

PE, PP, PS, etc. + starch: decomposing machine pellets

PE + fog-preventing dipper, stabilizer: dual-prevention machine pellets

PE, EVA, ABS, etc. + carbon black: black machine pellets

Colored Machine Pellets: PEMPP, ABS, AS, PA, EVA, PET + pigment and auxiliary

Intensified glass fibers and carbon fibers: PP, PBT, ABS, AS, PA, PC, POM, PPS, PET, etc. + long fibers, carbon fibers, crystals and so on

Various Cables: HDPE, LDPE, LLDPE, MDPE, EVA, PVC, PP, insulating cables, coatings, PE peroxide, silicon alkyl cross cables

Special Materials: EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material

Reaction Extruding: Polyamide condensate, polyamide melting polymerization, polyamide polyethylene-adding, polycarbonate condensate, etc.

Exhausting and Volatilization: Polystyrene oxide, high-absorbing resin, chlorine sulfur polyethylene

Powder Paint: Polyester, ring oxide, lactide, polyurethane, acrylate

FAQ

Â

1. Q: How about Haisi?

R: Nanjing Haisi Extrusion Equipment Co., Ltd. is a High-Tech company. Our firm is composed of a strong team which has substantial experience in R&D, manufacture, technique and sales service and has specialized in extruder industry for ten years, leading screw barrel manufacturer in China.

2. Q: What's Haisi capacity?

R: Company is in strict accordance with CE and ISO9001 quality certification system. There are over 200 models of extruders and spare parts.

Â

3. Q: What's the delivery time?

R: For regular size, we have finished stock and semi-finished stock, 2 weeks max enough for customized, normally 3~4 weeks.

Â

4. Q: How about Haisi screw extruder quality and price?

R: Germany Technical invested, top quality in China with competitive price and global after-sale service

5. Q: What's the life time and guarantee buy from Haisi screw extruder?

R: 3~5 years life time for nitriding ones and bimetallic ones will be longer. One year min. Guarantee.

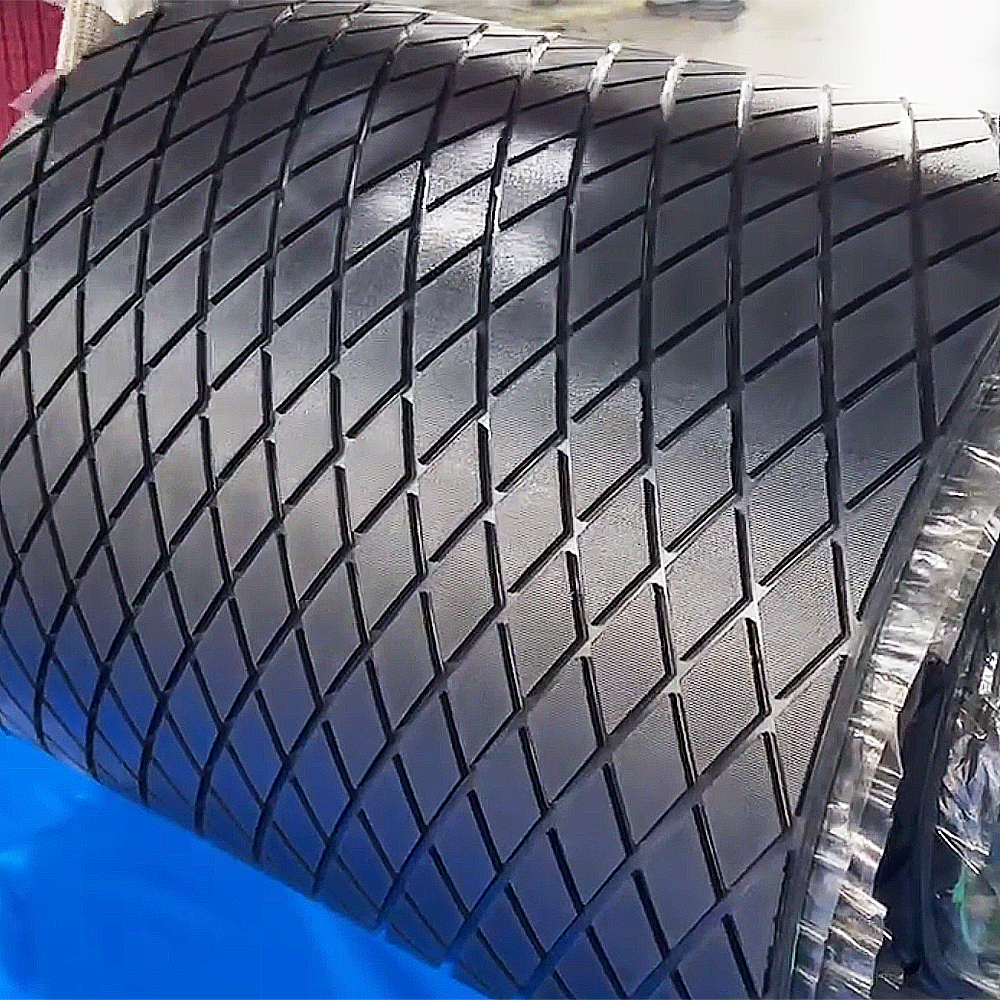

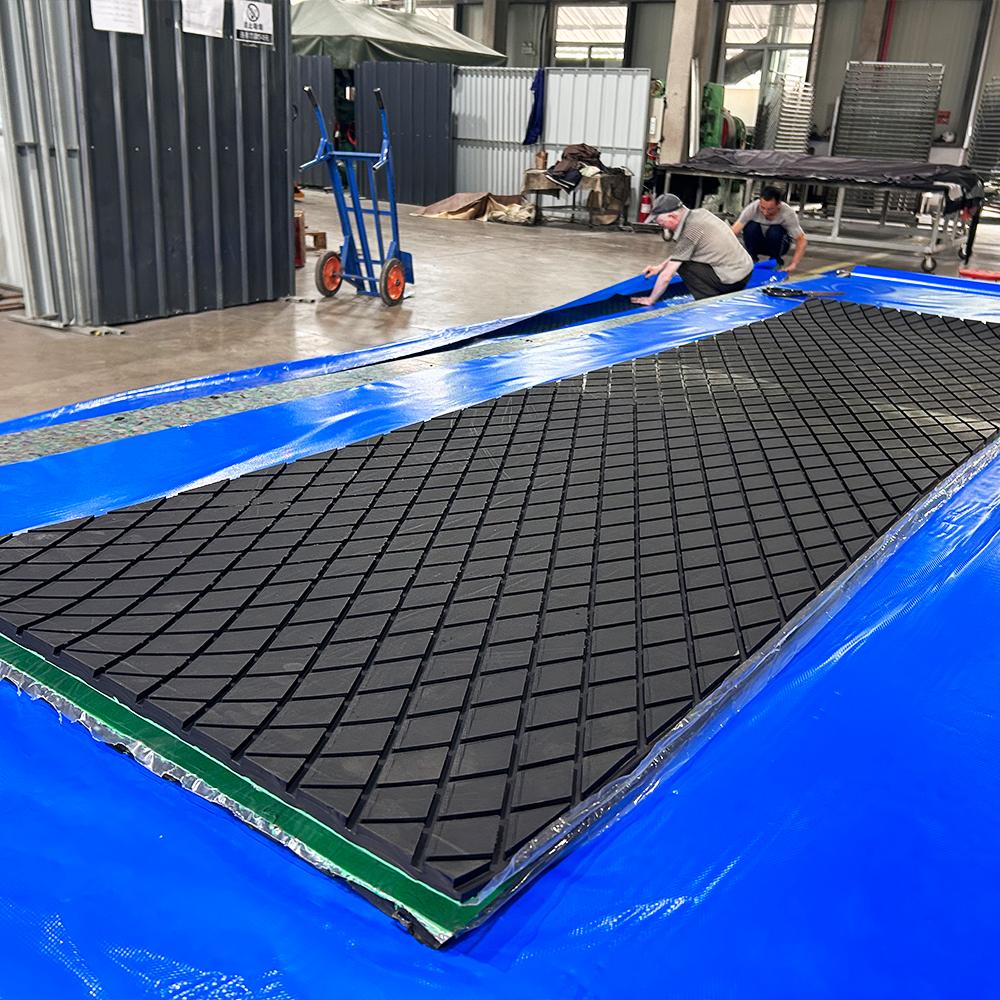

Roller Covered Rhombic Rubber Sheet

rhombic rubber sheet,pulley lagging rubber sheet,rubber pulley lagging,Roller covered rhombic rubber sheet,rhombic rubber plate

Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com